Marine Survey & Consultancy

Your Safety is Our Signature

That Saves Your Time!

Our Mission

Flots Maritime strives to provide quality and proficient services to the clients, realizing the needs to have Professional services at most effective manner and also have vast experience in marine industry.

Our Vision

To emerge as leading regional marine solution provider, capable of blending International standard with local Knowledge with highly qualified and experienced team of Master Mariners, Marine Engineers, Marine Surveyors, Naval Architect, Designer, Planner, International Business Development Managers and Operational Staffs to take care of all Marine needs of our esteemed clients.

Welcome to Flots Maritime

We address the marine survey and consultancy requirements in UAE, India and Africa with unbiased survey reports and expert advices by organizing the combined effort of well experienced engineers, technologists and marines. We deliver our service on time without compromising on the quality. We strive for exceptionally high standards in all the services we offer.

Our Services

Bunkering survey

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it.

ON/OFF hire CONSUMABLES survey

We undertaken either before the vessel or structure is delivered into a charter, or redelivered from a charter.

Condition surveys

The survey report will include a detailed description of a vessel’s cargo spaces/deck areas structural condition, cargo space cleanliness, bunkers on board, listing of the vessel’s statutory certificates, portable securing equipment, etc.

Boat surveys

Our survey provide peace of mind and protection when buying a boat – whether new or secondhand – and in ensuring no important elements are missed in the vessel’s long-term maintenance.

Draft surveys

We enable ship operators, owners and engineers to conveniently calculate various important quantities without investing significant amounts of time on trivial computations. This saves both time and money, which are equally important for cargo and passenger-carrying vessels.

Cargo surveys

To securing the good conditions of your cargo, including General Cargo, Bagged Cargo, Refrigerated Cargo, Bulk cargo (grains / minerals), monitoring of loading/unloading cargo operations.

Damage surveys / Damage evaluation

We assess the extent of the damage in the hull, rig, systems, or elsewhere on the vessel. The report presents information on the probable causes of the damage, recommendations on repairs, and estimates the costs for such work.

Lashing surveys

We will monitor the safe handling and loading of the cargo units, give advice on proper stowage and verify that the cargo units are lashed and secured properly.

Towing / Sail away surveys

Our experienced surveyors will make sure the Fitness to Tow assignments must be carried perfectly prior to the departure. The scope of the survey will depend on the nature of the towing operations.

Container inspection

We provide comprehensive Container Inspection Service of teh extrior and interior of the container to make sure the unit is safe for shipping and properly certified.

Towing appliances inspection onboard vessels

Our survey will safe guard and comply with the safety regulations of different governing bodies to ensure the safety of standards, and safety systems of towing vessels.

Radio graphic testing [ RT ]

Is a set of testing services provided for a vessel to verify and confirm its readiness and safety for navigation in appropriate sea area. The condition of the ship and its equipment shall be maintained to conform with the provisions of the SOLAS regulations to ensure that the ship in all respects will remain fit to proceed to sea without danger to the ship or persons on board.

Ultra sonic testing [UT]

Ultrasonic testing is performed on steel and aluminum vessels to detect and quantify corrosion. It can also be used to measure the thickness and integrity of composite structures. Non-destructive testing and inspection of ships can be performed by an experienced ultrasonic technician.

Magnetic particle testing [ MPT]

This is a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. This process checks for surface discontinuities but can also reveal discontinuities slightly below the surface.

Dye penetrate testing [ DPT ]

Dye penetrant tests are used to detect surface defects such a fatigue cracks in crankshaft and screw shafts. The part to be tested is thoroughly cleaned, and a dry penetrant is sprayed on the cleaned area. If any surface defect is present, capillary attraction draws the dye into the cracks.

UT thickness gauging

Ultrasonic thickness measurement (UTM) for vesssels is a non-destructive testing method used to inspect the metal thickness of ship hulls, piping and steel structures.

Hot work permit

Hot works in Ships involve many hazards, and careful consideration will need to be made for safe planning and execution. Our techncial team will provide essential check items before doing any hot work-related maintenance job.

Confined space entry permit

We prepare permit which is relevant and as accurate as possible.It will state the location and details of the work to be done, the nature and results of any preliminary tests carried out, the measures undertaken to make the job safe and the safeguards that need to be taken during the operation.

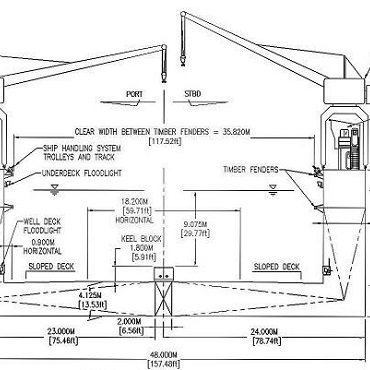

Preparation of DRY DOCKING SPECIFICATION

The preparation of the specification document for a vessel drydocking or conversion can be very time consuming. The package is designed to help marine superintendents handle drydocking and conversion specifications with minimal effort.

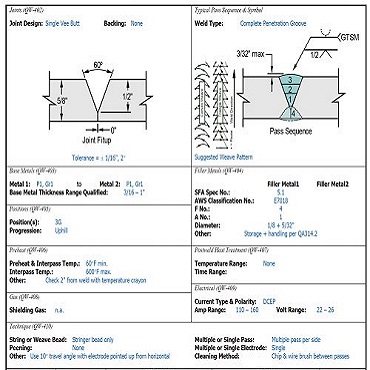

Preparation of WPS ( Welding procedure specification)

The Welding Procedure Specification is a required document for all code welding. Based on requirements different code must be qualified. The WPS outlines all of the parameters required to perform your welding operation.

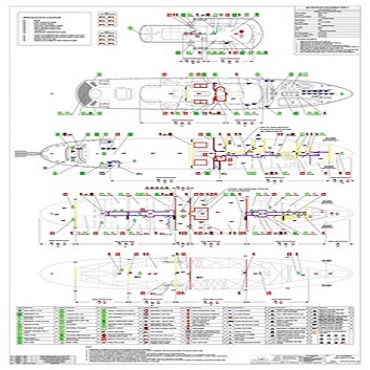

All types of NAVAL ARCHITECTURE CALCULATIONS.

We will prepare all necessary technical calculations, drawings and specifications as required from concept and feasibility studies to complete class approval documentation.

Bunkering survey

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it.

ON/OFF hire CONSUMABLES survey

We undertaken either before the vessel or structure is delivered into a charter, or redelivered from a charter.

Condition surveys

The survey report will include a detailed description of a vessel’s cargo spaces/deck areas structural condition, cargo space cleanliness, bunkers on board, listing of the vessel’s statutory certificates, portable securing equipment, etc.

Boat surveys

Our survey provide peace of mind and protection when buying a boat – whether new or secondhand – and in ensuring no important elements are missed in the vessel’s long-term maintenance.

Draft surveys

We enable ship operators, owners and engineers to conveniently calculate various important quantities without investing significant amounts of time on trivial computations. This saves both time and money, which are equally important for cargo and passenger-carrying vessels.

Cargo surveys

To securing the good conditions of your cargo, including General Cargo, Bagged Cargo, Refrigerated Cargo, Bulk cargo (grains / minerals), monitoring of loading/unloading cargo operations.

Damage surveys / Damage evaluation

We assess the extent of the damage in the hull, rig, systems, or elsewhere on the vessel. The report presents information on the probable causes of the damage, recommendations on repairs, and estimates the costs for such work.

Lashing surveys

We will monitor the safe handling and loading of the cargo units, give advice on proper stowage and verify that the cargo units are lashed and secured properly.

Towing / Sail away surveys

Our experienced surveyors will make sure the Fitness to Tow assignments must be carried perfectly prior to the departure. The scope of the survey will depend on the nature of the towing operations.

Container inspection

We provide comprehensive Container Inspection Service of teh extrior and interior of the container to make sure the unit is safe for shipping and properly certified.

Towing appliances inspection onboard vessels

Our survey will safe guard and comply with the safety regulations of different governing bodies to ensure the safety of standards, and safety systems of towing vessels.

Radio graphic testing [ RT ]

Is a set of testing services provided for a vessel to verify and confirm its readiness and safety for navigation in appropriate sea area. The condition of the ship and its equipment shall be maintained to conform with the provisions of the SOLAS regulations to ensure that the ship in all respects will remain fit to proceed to sea without danger to the ship or persons on board.

Ultra sonic testing [UT]

Ultrasonic testing is performed on steel and aluminum vessels to detect and quantify corrosion. It can also be used to measure the thickness and integrity of composite structures. Non-destructive testing and inspection of ships can be performed by an experienced ultrasonic technician.

Magnetic particle testing [ MPT]

This is a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. This process checks for surface discontinuities but can also reveal discontinuities slightly below the surface.

Dye penetrate testing [ DPT ]

Dye penetrant tests are used to detect surface defects such a fatigue cracks in crankshaft and screw shafts. The part to be tested is thoroughly cleaned, and a dry penetrant is sprayed on the cleaned area. If any surface defect is present, capillary attraction draws the dye into the cracks.

UT thickness gauging

Ultrasonic thickness measurement (UTM) for vesssels is a non-destructive testing method used to inspect the metal thickness of ship hulls, piping and steel structures.

Hot work permit

Hot works in Ships involve many hazards, and careful consideration will need to be made for safe planning and execution. Our techncial team will provide essential check items before doing any hot work-related maintenance job.

Confined space entry permit

We prepare permit which is relevant and as accurate as possible.It will state the location and details of the work to be done, the nature and results of any preliminary tests carried out, the measures undertaken to make the job safe and the safeguards that need to be taken during the operation.

Preparation of DRY DOCKING SPECIFICATION

The preparation of the specification document for a vessel drydocking or conversion can be very time consuming. The package is designed to help marine superintendents handle drydocking and conversion specifications with minimal effort.

Preparation of WPS (Welding procedure specification)

The Welding Procedure Specification is a required document for all code welding. Based on requirements different code must be qualified. The WPS outlines all of the parameters required to perform your welding operation.

All types of NAVAL ARCHITECTURE CALCULATIONS.

We will prepare all necessary technical calculations, drawings and specifications as required from concept and feasibility studies to complete class approval documentation.

We continue to pursue that same vision in today's complex, uncertain world, working every day

In All ports of UAE

We provide service in all ports in UAE like Jabel Ali Port, Hamriyah Port, Ajman Port, Khorfakkan Port etc.

Experienced Engineers

Our team is a group of engineers with good experience in all the ports of UAE. Also with very good experience in Ship building and repair in India, UAE and Africa.

Realiable

Our Local Knowledge in Marine Network is one of our most valuable assets, which has Value added to Marine & shipping Field.

Proper Measurements

Standardized, Transparent System, Team work and Clear communication.

Relevant Certifications

Our facilities meet high security requirements and are certified to the highest local standards.

Safety Checks

We are having an uncompromising attitude towards safety and environment.

Sample Collection & Documentation

Single point of contact for your needs. We Provide proper and timely update to the concerned person.

Class Rules & Code Practices

Well Versed with different class rules and regulations like those of American Bureau of Shipping (ABS), Germanischer Lloyds, Lloyd’s Register of Shipping, DNV.

Flots Maritime team is the best of the best, and expertly trained team members who take the extra step and go the extra mile, all to fulfill our dedicated promise to deliver innovative and dynamic solutions to our customers to fit the needs of a rapidly changing global environment.

Flots Maritime team is the best of the best, and expertly trained team members who take the extra step and go the extra mile, all to fulfill our dedicated promise to deliver innovative and dynamic solutions to our customers to fit the needs of a rapidly changing global environment.

Flots Maritime team is the best of the best, and expertly trained team members who take the extra step and go the extra mile, all to fulfill our dedicated promise to deliver innovative and dynamic solutions to our customers to fit the needs of a rapidly changing global environment.