Overview

One of the leading Marine and Cargo surveyors by providing high quality in Marine services in UAE & GCC Countries, India. Our Core Business is to provide quality in Marine services like Loading & Discharging Cargo Operations, Tally and Port Captaincy Etc... Flots Marine is emerging as leading regional marine solution provider, capable of blending International standard with local Knowledge. Further Flots Marine strives to provide quality and proficient services to the clients, Realizing the needs to have Professional services at most effective manner and also have vast experience in marine industry with team of Master Mariners, Marine Engineers, Marine Surveyors, Naval Architect, Designer, Planner, International Business Development Managers and Operational Staffs to take care of all Marine needs of our esteemed clients. Every Officer in our team are academically highly qualified with double post graduates.

Ship Building, Repair Supervision and Project Management

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Preperation of Dry Docking Specification

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Preperation of Welding Procedure Specification - WPS

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

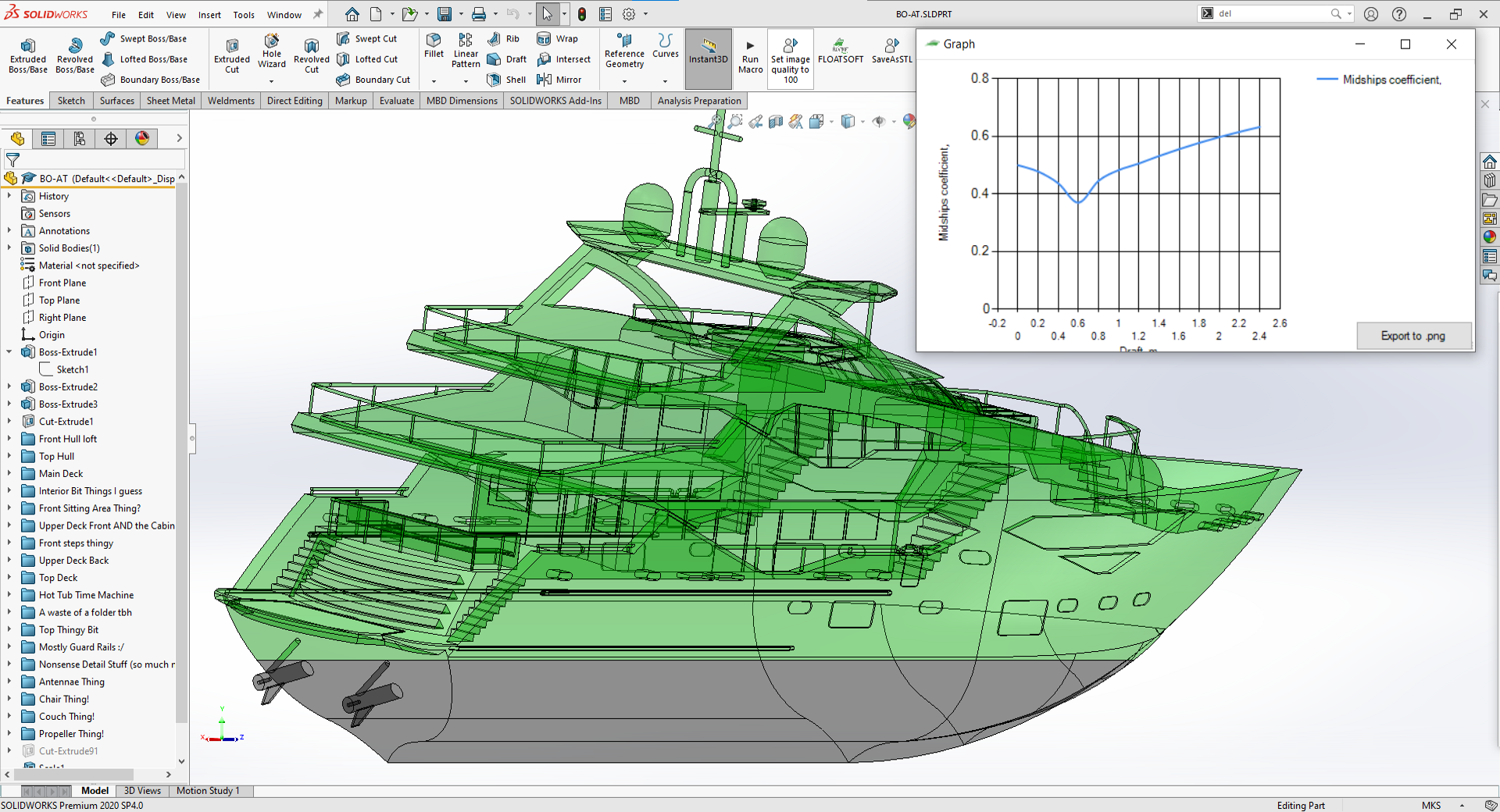

All Types of Naval Architecture Calculations

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

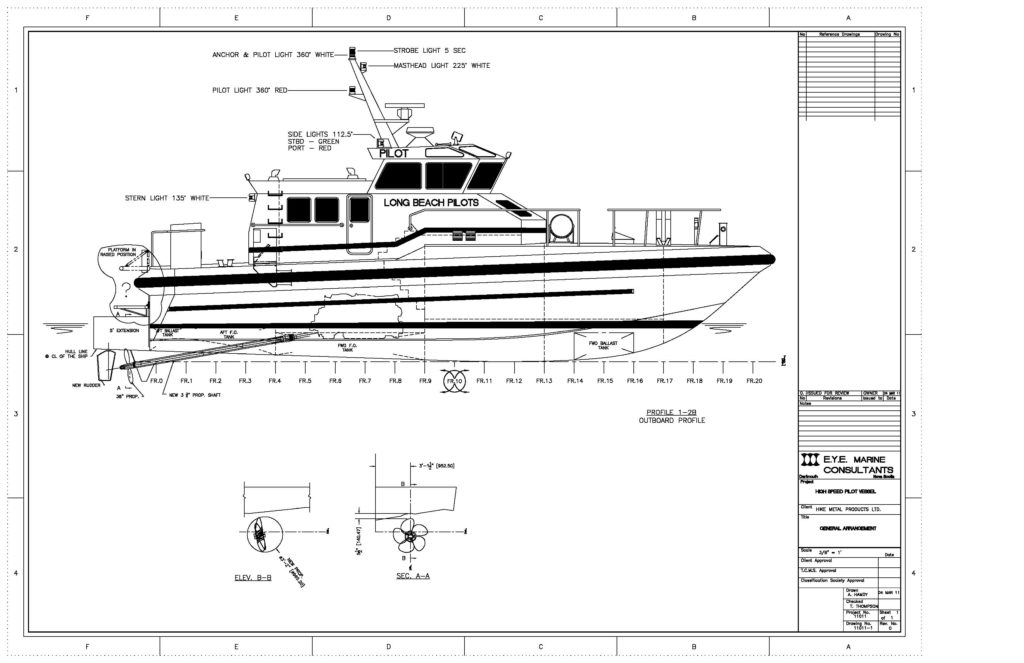

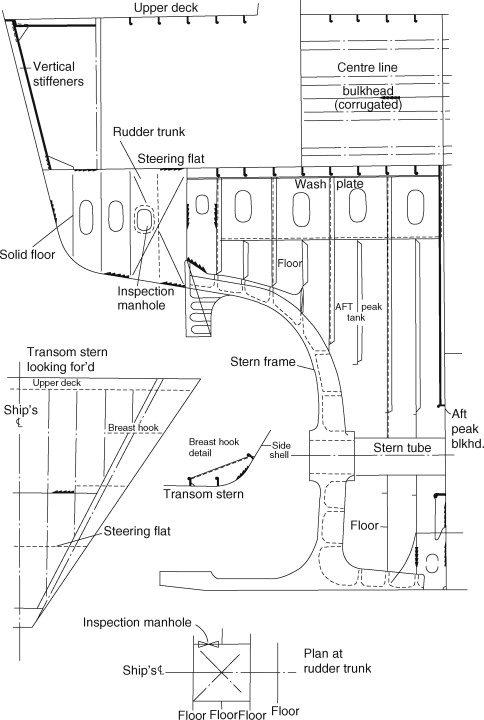

All Types of Drawings

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Offshore Lifting Calculations, Load Out & Transportation Analysis

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Design and Analysis for New Construction of Ships / Offshore Vessels

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Plan Approval and Calculations

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.

Hydrostatics and Hydrodynamics

Bunker pricing and fuel quality are critical components to a vessel’s operating costs. Fuel cost can be as much as 60% of a vessels operating budget. Off specification fuel can potentially damage vessel engines and boilers. A bunker survey is relatively cheap insurance to deter product diversion. A detailed bunker survey will confirm fuel delivery and report bunker fuel shortages. If there is an unaccountable gain in bunker tanks or bunker volumes cannot be reconciled with bunker consumption, Letter of Protests are issued and an investigation can identify the causes.

Bunker fuel measurement, sampling & testing are conducted. We follow industry standards and accreditations, ISO 13739, SS600, TR48, ISO 17020 and ISO 17025. We will also follow if client is having any specific proceedures in addition to it

Our engineers will be doing below procedual steps for properly conducting the bunker survey.

1. Identify and records the number of Bunker Tanks, Depth of each Tank, Reference Height

and Measuring Method (Ullage or Sounding).

2. Obtain and record the previous Bunker Report, time and place the bunkers were supplied

along with the oil density.

3. Records the quantity of bunker onboard when the ship arrived (arrival Condition) as per

Engine Log Book.

4. Check the Ship’s Draft Marks to get the Ship Trim for Trim correction and check the ship

Inclination or Listing for List Correction.

5. Gauge each Bunker Tank and record the level of Oil on the tank along with the oil

temperature.

6. Sample and water cut each bunker tankWe pride ourselves on providing the best transport and shipping.